Lame Duck Day: Turnkey garage construction

February 6 marks a rather unusual day of action: Lame Duck Day. The term originally comes from politics and economics and describes situations in which processes come to a standstill. As a result, decisions are postponed while projects fail to progress.

This kind of scenario is one that many builders are familiar with, as it often mirrors their own experience. This is particularly true when they are building a garage.

What initially starts out as a manageable project can, however, quickly turn into a test of patience when traditional construction methods are used. For example, a lack of tradespeople, long construction times, as well as weather-related delays often make turnkey garage projects difficult. In addition, unclear responsibilities contribute to the project ultimately becoming a “lame duck.”

Why garage construction often stalls

Many builders underestimate the effort involved in building a turnkey garage. What sounds simple at first quickly becomes complex in practice. There are often long waiting times for available tradespeople. In addition, several trades have to be coordinated. This results in open construction sites that drag on for weeks. Added to this is the high dependence on the weather. Rain, frost, or heat can delay construction. That’s why garage installation costs, garage construction time, and completion are often difficult to calculate.

Especially with brick garages, one step follows another. If one step is delayed, the entire project comes to a standstill. Anyone who wants to build a turnkey garage is therefore looking for a better solution.

The alternative: turnkey prefabricated garage

Anyone planning a prefabricated garage or wanting to buy a garage consciously chooses short construction times and less stress. Such a garage is completely planned, produced in the factory, and then delivered and assembled.

The result is therefore a garage that is ready to use right away—without the need for many different tradespeople, without a long construction phase, and without additional risks. Especially in Germany, more and more builders are opting for this approach, as it offers a particularly high degree of safety as well as convenience.

In most cases, a prefabricated concrete garage is chosen, which is manufactured under controlled conditions in the factory. As a result, quality, stability, and dimensional accuracy remain consistently high. This form of solid garage construction offers clear advantages, because the benefits of a precast concrete garage lie primarily in its high level of planning reliability. All steps can be precisely defined in advance, so that delays can be avoided and additional costs can usually be ruled out.

Delivery and assembly therefore only take place once all preparations have been completed. By this point, the foundation is already in place, there is sufficient space available on the property, and organizational matters—such as whether a building permit is required—have been clarified in advance. This, in turn, ensures that the garage can be built smoothly and completed without interruption.

Don’t miss out on any more information!

Don’t want to miss out on creative ideas for your garage? Whether it’s clever uses, new products, or exclusive promotions, our ZAPF newsletter will keep you one step ahead. Get regular inspiration delivered straight to your inbox and stay up to date on how versatile a ZAPF garage can really be. Simply sign up and become part of our community – it’s easy and, of course, free of charge.

Garage assembly: clear process with KTM and crane

The assembly of precast concrete garages at ZAPF follows a clearly defined and proven process, which ensures maximum efficiency and reliability. In most cases, the so-called KTM vehicle is used. This KTM assembly therefore combines transport, delivery, and installation of the garage in a single step. As a result, the garage is brought directly from the factory to the construction site and placed precisely on the prepared foundation.

Before assembly begins, everything is planned in detail. For example, the foundation meets the required specifications, the access road has been checked, and sufficient space is available on the property. This preparation ensures that assembly can begin without delay. During installation, the garage is precisely aligned and secured using the KTM vehicle. Once installed, it is permanently fixed in place and ready for immediate use.

A major advantage of this system is therefore the high degree of planning reliability. Since garage installation is not dependent on the weather, this ensures that the agreed deadline is met. In many cases, the garage can be installed in a single day, without any open construction site.

Only when circumstances require it—for example, in the case of particularly narrow plots, obstacles, or special space conditions—is the garage additionally assembled using a crane. However, this crane assembly is also carefully checked and organized in advance, so that the garage is placed safely and with millimeter precision.

Overall, the combination of ZAPF garage assembly, KTM assembly, and the optional crane solution ensures a fast, predictable, and reliable process—without construction stress and without downtime.

Delivery and assembly from a single source – fast and stress-free

With ZAPF garage assembly, builders receive a well-thought-out solution with garage delivery and assembly. The garage is not only delivered, but also professionally assembled and handed over fully installed. This means there is no open construction site and no further work is necessary.

This makes it possible to build the garage without any stress. Many customers report positive experiences with prefabricated garages, saying that they were able to build their garage without any construction time or tradespeople. Planning, delivery, and installation all fit together seamlessly.

At the same time, a turnkey prefabricated garage can be built quickly. Convenient garage construction mainly means no coordination of different trades, no follow-up, and no risk. All steps are clearly defined and scheduled.

In addition, you can plan doors, windows, and other options in advance. Interested parties can easily obtain quotes or request a non-binding offer.

The prefabricated garage also shows its strengths on difficult plots of land. Narrow driveways, existing outdoor facilities, or limited space are not uncommon. Thanks to a crane, the prefabricated garage can be erected even if only limited space is available. This ensures that the garage is positioned safely and precisely without damaging other areas of the property.

Who is a turnkey garage ideal for?

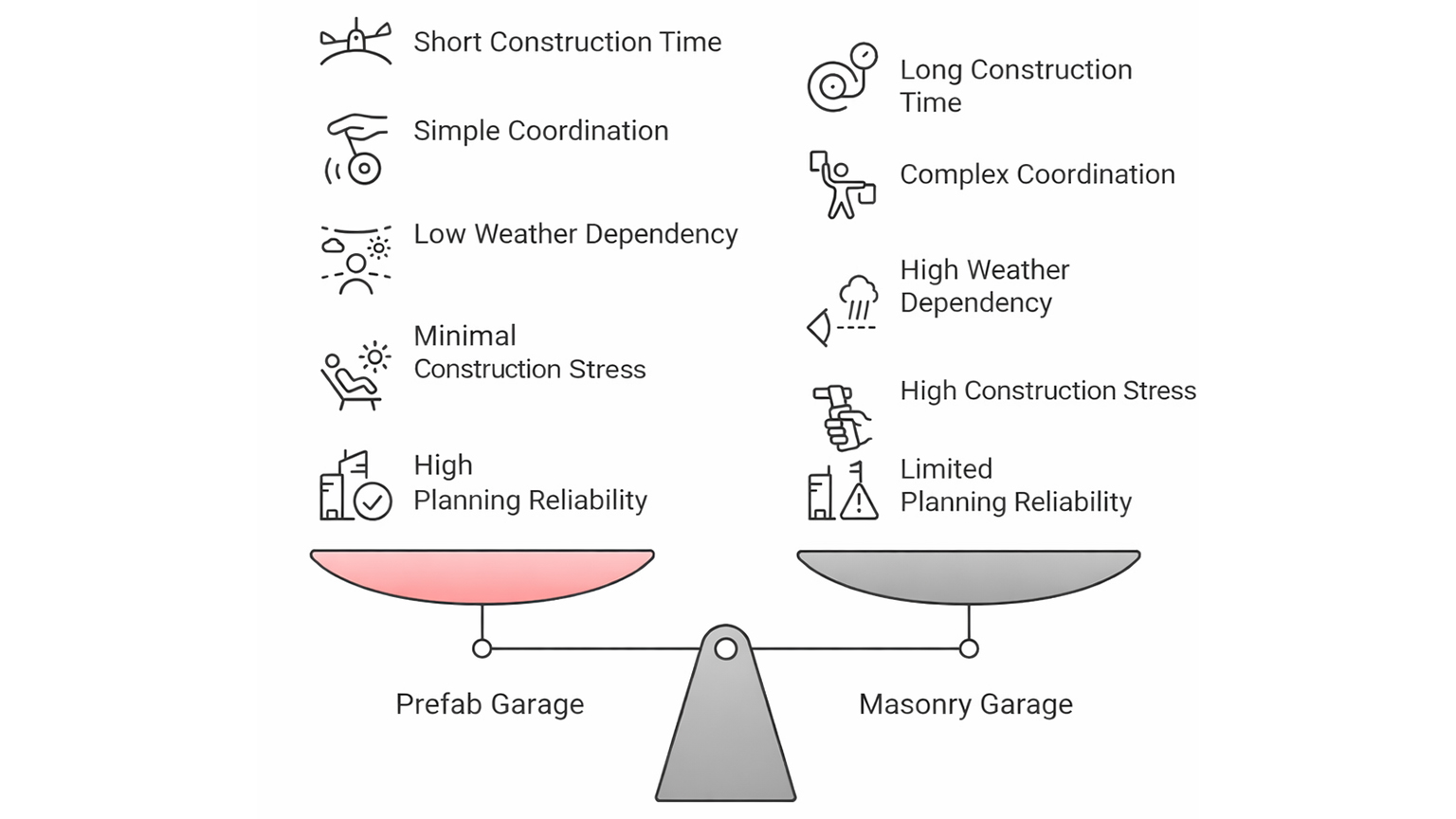

When making a direct comparison between a brick garage and a prefabricated concrete garage, it quickly becomes apparent that there are clear differences not only in the construction process but also in overall planning. While a brick garage typically requires a longer construction period and therefore the coordination of several different trades, a prefabricated concrete garage, by contrast, offers a clearly structured and turnkey process from start to finish. Moreover, many individual work steps are defined well in advance, which consequently and to a significant extent reduces the organizational effort required from builders.

In addition to these aspects, weather dependency also plays a decisive role in this context. Whereas construction work on brick garages can be delayed not only by unfavorable weather conditions but also by seasonal influences, prefabricated concrete garages, on the other hand, can be built largely independently of such external factors. As a result, this leads to greater reliability in scheduling and, at the same time, makes it considerably easier to integrate the garage into existing or parallel construction projects.

Furthermore, another important difference lies specifically in planning and cost certainty. While unforeseen additional work can often lead to rising costs in the case of a brick garage, a precast concrete garage, by comparison, offers a high degree of planning certainty because all services are clearly defined in advance. This, in turn, not only reduces construction-related stress, but also enables a transparent, predictable, and therefore easily manageable construction phase.

For these reasons, a turnkey garage is particularly suitable for builders with limited time resources, as well as for families who want to plan their garage reliably and far in advance, and also for people who prefer not to organize the construction process themselves. In addition, homeowners who place great value on clear structures and clearly defined processes benefit equally from this solution. Precisely because a ZAPF garage is highly versatile, it can therefore be adapted not only to many different requirements but also to a wide range of individual planning situations.

Garage without downtime

The day of the lame duck makes it clear how frustrating downtime can be. However, this downtime can be avoided when building a garage. When you choose a turnkey prefabricated garage, you can count on clear processes, short distances, and reliable deadlines right from the start.

With delivery and assembly as well as precise planning, we can build your garage quickly – ready to use, without unnecessary delays. The assembly team works efficiently, often within a short time, so that you can use your garage right away.

Your advantages at a glance:

- Garage without construction stress

- Garage without long construction times

- Garage quickly assembled

- Stress-free garage construction

Stay up to date, discover new products or exclusive promotions, and subscribe to the ZAPF newsletter. There you will also find frequently asked questions about planning, assembly, and equipping your garage.

Or in other words:

On the day of the lame duck, everything can come to a standstill – except your garage.

Configure your garage in 3D now and experience it virtually on your own property!

With our garage configurator, you can easily and intuitively put together the size, equipment, doors, windows, and extras in just a few steps. We will then arrange a non-binding consultation appointment with you, on the basis of which you will receive an individual offer, naturally at a fair price and with no obligation to buy. Experience your configured garage in impressive 3D visualization during the non-binding consultation appointment.